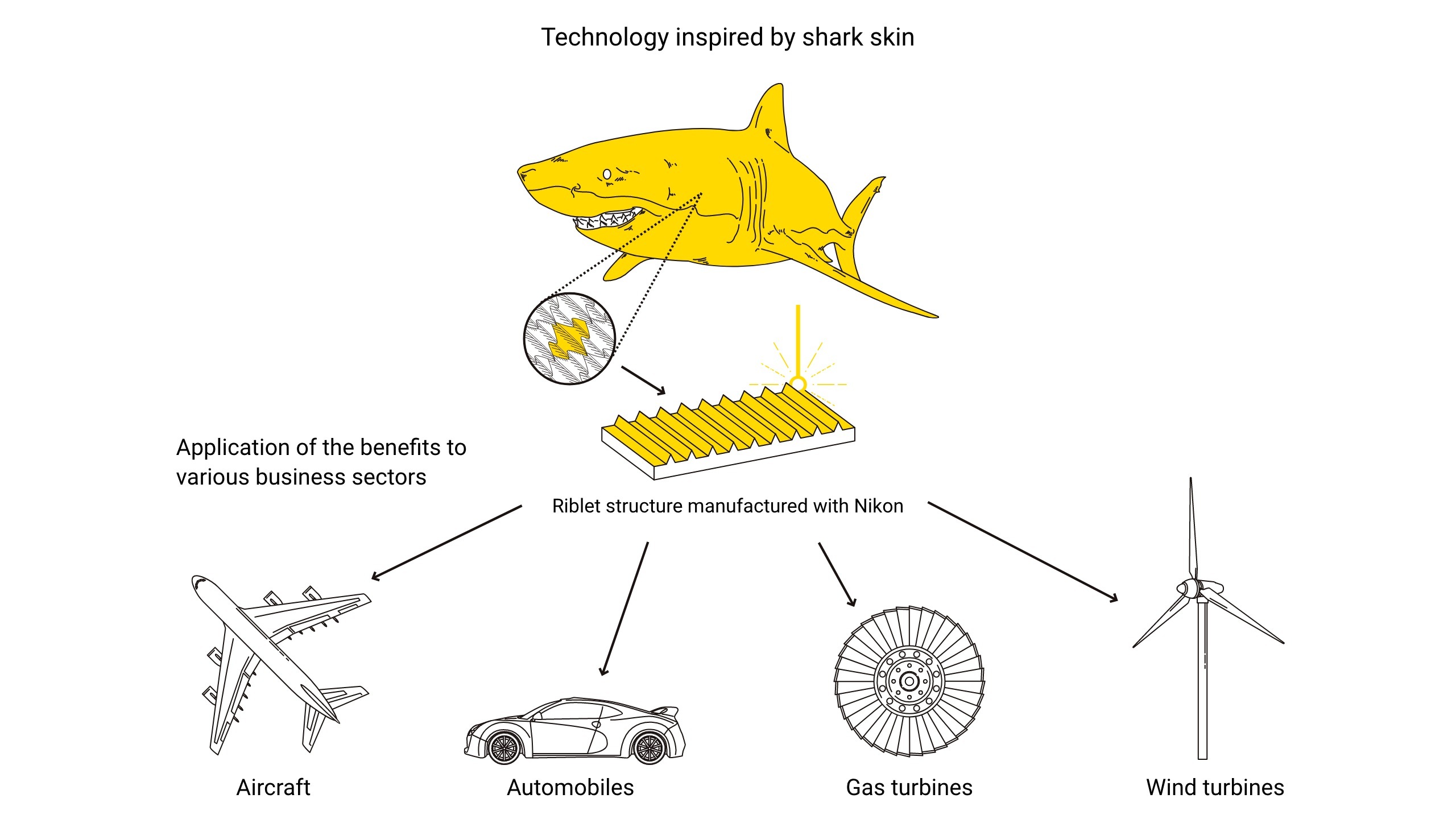

The tech world has all the time taken inspiration from the pure world, and Nikon lately showcased its progressive riblet-processing know-how.

Designed for aviation, water and wind energy, this biometric know-how mimics the unimaginable floor construction of shark pores and skin, utilizing Nikon’s proprietary laser processing to create riblets.

Riblets are surfaces with grooves positioned on plane, significantly on the wings and fuselage the place air currents are sturdy, to scale back drag and enhance gasoline effectivity, and cut back CO2. emissions.

Nikon predicts that its shark pores and skin know-how will enhance gasoline consumption on aircrafts by 2%, cut back annual gasoline prices by ¥8 billion (round $51 million / £41 million / AU$82 million). It additionally believes that it may minimize CO2 emissions by 300 tons.

Nikon has been engaged on this know-how for some years as a part of its sustainability efforts, serving to plane in direction of a carbon-neutral future. It first began making use of its riblet know-how in 2019, and displayed it at CES final 12 months. Showcasing it this 12 months’s present, Nikon wished to exhibit its vital developments within the wind turbine business.

Nikon’s developments in riblet know-how are already making waves in a number of industries. “One in all our vital developments this 12 months is the applying of Riblet know-how to precise wind generators,” stated Mutsuki Nakayama, a Nikon consultant stated to Fascinating Engineering.

“We’ve carried out Riblet know-how on plane operated by ANA Airways and Japan Airways in Japan. At the moment, we’re additionally engaged on making use of it to helicopter blades to additional cut back drag and enhance effectivity.”

So, why sharks?

Sharks have existed for over 400 million years, they usually have advanced a singular texture on their pores and skin of longitudinal grooves that helps them glide by means of the water with little or no resistance. By replicating the engineering of shark pores and skin, Nikon has developed a strategy to apply riblets to varied supplies, similar to jet engines, to enhance their power effectivity.

“Riblet is a brand new know-how developed by Nikon, impressed by the feel of shark pores and skin,” Nakayama added. “It originated from our lithography enterprise and leverages our experience in laser machining – certainly one of Nikon’s largest belongings. By utilizing laser etching, we create tiny constructions on the surfaces of varied supplies similar to movies, metals, resins, and coatings. These microstructures mimic shark pores and skin and assist cut back friction by about 7%.”

Nikon’s laser-based manufacturing of riblets presents a number of key benefits over conventional strategies that depend on resin movies, which have limitations like warmth resistance and sturdiness.

Its riblets could be utilized to three-dimensional curved surfaces because the laser know-how ensures exact software, whereas conventional strategies might trigger wrinkles or peeling.

Regardless of this large development, Nikon did face difficulties – significantly in ramping up manufacturing to match vital demand.

“One of many most important challenges was the throughput of the laser processing. Initially, the laser processing time was fairly sluggish, which restricted our capacity to scale up manufacturing. The COVID-19 pandemic additionally impacted our progress, however we’re repeatedly working to enhance the method,” stated Nakayama.

You may also like…

Check out our guides to the greatest Nikon cameras and the greatest Nikon lenses. You would possibly even have an interest within the greatest waterproof and underwater cameras!